Dissolved Air Flotation

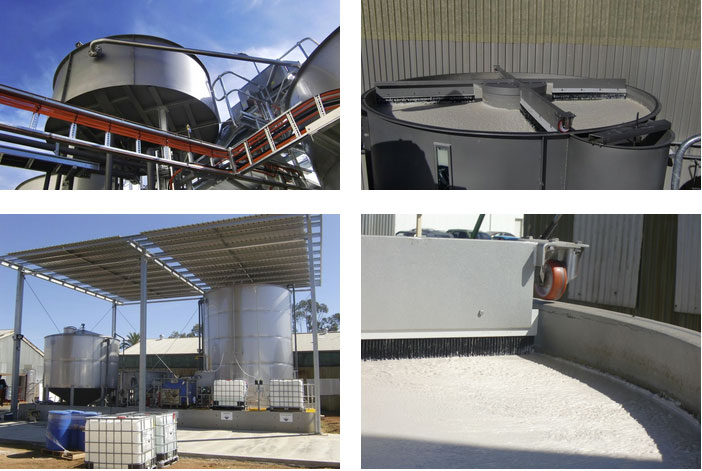

CST-DAF

A truly new system of Dissolved Air Flotation

FEATURES

CST-DAF is a high rate DAF flotation unit.

Unprecedented clarification and thickening efficiency is attained by the new hydro direct system combined with the unique micro-bubble screening system: a recent exclusive break-through innovation developed by Aqua Engineering.

BENEFITS

- High separation and sludge thickening efficiency

- High air dissolving rate (>90%)

- Reduced energy and chemicals consumption

- Low water head of the flotation cell

- Smplified and easy installation

- Can retrofit to existing circular tanks

- Optional fully automatic operation

- Know-how for implementing the flotation unit in the WWTP or in the production line

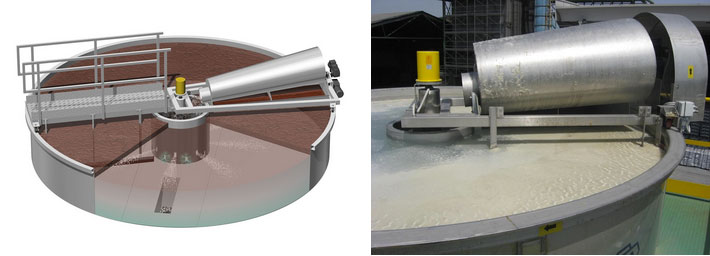

PRINCIPLE OF OPERATION

Feed stream, clarified effluent and sludge float are all conveyed through the unique multi functional central column. Both feed and clear streams follow uniform radial trajectories through different sections of the liquid volume in the cell. The feed mix, is pushed immediately to the surface due to the floating action of the micro air bubbles. Thanks to the specifically designed inlet slots, the inflow is distributed uniformly throughout the flotation area (hydro direct system).

Before reaching the exit slots, the clear bottom layer is forced to pass through a filtering micro bubbles bed provided by the high efficiency air-dissolving reactor. This unique system allows for an extra available flotation area and separation performances superior to any other DAF units currently in the market.

A radial skimmer with a rotating double scoop removes the sludge float continuously without disturbing the sludge blanket.