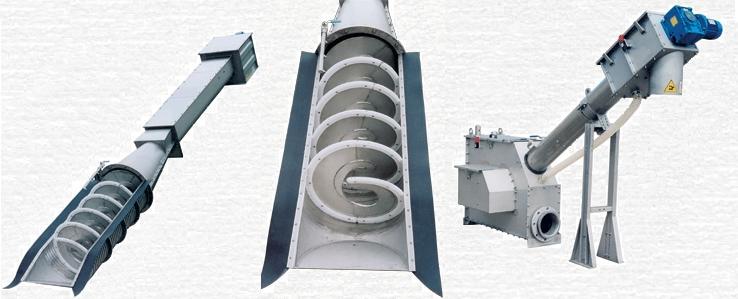

Screen Compactors and Screen Extractors

Description and Working Principle

The Screen Compactor is a slimline combined machine consisting of:

- Screen: a drilled or wedge-wire metal screen section with mesh sizes 0.25 mm to 10 mm

- Conveyor: to elevate the captured solids out of the effluent and de-water by gravity conveying them towards the pressing zone

- Press: de-watering and compressing the screenings to give a volume reduction of up to 40%

The Screen Extractor comes without the pressing section.

The special design and structural simplicity of the Screen Compactor and Screen

Throughput rates up to 1000 m³/h.

Performance and Technical Features

RANGE AND PERFORMANCE

- Screen mesh size ranging from 0.25 mm to 10 mm

- Screen width ranging from 200 mm to 700 mm

Volume reduction up to 40%

DESIGN FEATURES

- Stainless steel housing

- Shaftless spiral screw made of carbon steel or stainless steel

- SFC = screen press for channel installation

- SFC/T = screen press installed in a self-supporting container

- SF = screen without press for channel installation

- ST/T = screen without press in a self-supporting container

ACCESSORIES

- Continuous bagging unit

- Heating for cold regions

- Screenings washing for faecal removal

SPECIAL SCREENS

APPLICATIONS

Municipal waste water treatment plants:

- At entrance of plant with average mesh size of 5 mm

- As fine screen after coarse screen with average mesh size of 2 mm

Industrial effluent screening in:

- Tanneries at discharge (mesh size ranging from 0.5 mm to 5 mm depending on the application)

- Tomato processing at discharge before the reutilization of the water (mesh size ranging from 0.5 mm to 5 mm)

- Vegetable processing (peas, beans, potatoes) at discharge (mesh size ranging from 5 mm to 7 mm)

- White fish processing at discharge (mesh size ranging from 0.5 mm to 5.0 mm)

- Paper mills for removal of plastics, fibre, wood chips (5.0 mm or less)

- Airport services for discharging aircraft lavatories (mesh size 5 mm)

- Motorway services for lavatory discharge (mesh size ranging from 3 mm to 5 mm)

- Cattle and pig abattoirs before discharge (mesh size 5 mm)

- Dairy processing before discharge (mesh size 5 mm)

- Breweries before discharge (mesh size 5 mm)

- Drinks processing before discharge (mesh size ranging from 3 mm to 7 mm)

- Wineries before discharge (mesh size 2 mm)

- Textiles before discharge (mesh size 2 mm)

- Supermarkets before discharge (mesh size 5 mm)

- Alpine resorts before discharge (mesh size ranging from 2 mm to 5 mm)

- Tourist villages before the discharge (mesh size ranging from 2 mm to 7 mm)

- Chemicals before discharge (mesh size ranging from 1 mm to 7 mm)

- Cattle breeding before the discharge

- Pig farms (using a low flow rate of 5 to 10 l/s with mesh size of 0.5 mm Screen Press works as a sludge thickening unit)

Winery wastes at 0.5 mm to 3.0 mm

OPTION – (see related links at the top right of page)

– SF model, without compacting zone, has been developed mainly to be used in industries where solids do not require any forced dewatering (e.g. plastics)

Advantages and Innovative Features

- Absence of bearings

- No mechanical components in contact with the product handled

- Low speed

- Shaftless spiral, therefore no jamming or blocking even if with fibrous products

- Volume reduction up to 40% and more depending on the product

Photos: click for Presentation