Advanced wastewater fine screening technology from CST Wastewater Solutions features headworks designed for easy installation, high screening efficiency and low-maintenance over diverse municipal and industrial wastewater treatment applications encountered locally and globally.

The robustly engineered horizontal in-channel rotary drum screening technology has already been proven in some of the notoriously variable conditions of its native Australasia, where it has been installed to perform cost-efficiently while curtailing blockages, environmental spills, maintenance and associated OH&S issues in conditions that can quickly switch from drought to flood, from sandy and stony to muddy and lush.

“Efficient headworks are vital to all the downstream purification and recycling process stages in a wastewater treatment plant, regardless of the location and input. Unless solids are efficiently separated out from wastewater at the start of the purification process, you are inviting trouble into the system – and this can cost operators dearly in terms of downtime, environmental risk and clean-up costs and OH&S hazards for the teams involved,” says CST Wastewater Solutions Managing Director Mr Michael Bambridge.

Mr Bambridge – who has more than 30 years of wastewater installation and operational experience throughout the Asia-Pacific region – says the municipal and industrial applications and inputs for which CST’s rotary fine screen technology is engineered reflect the hugely diverse inputs and needs encountered by different municipalities throughout the world.

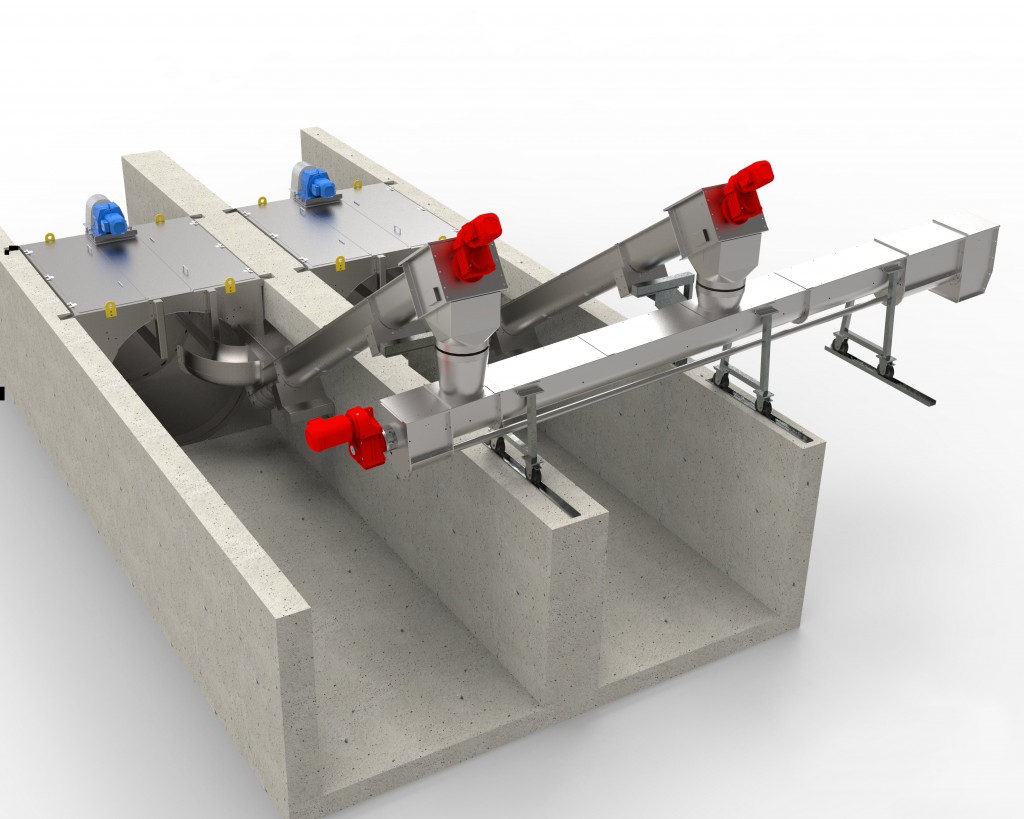

Functional layout of CST Wastewater Solutions’ In-Channel Rotary Drum technology

“We are especially mindful of the fact that many lean and efficient municipalities can’t afford the luxury of technologies that need the engineering support that many local bodies don’t have on-staff these days. This is the same in Australasia, where CST has been operating for more than 30 years.”

“So we have designed and built our low-maintenance, quality stainless steel technology to provide the simplest but most efficient technology available, proven on multiple MBR plants to perform outstandingly well in the diverse separation tasks of inlet headworks.

“The system is built to be versatile, flexible and robust, because these tasks vary not only from place to place, but day-to-day and week-to-week as loads on the system change.”

“WWTPs have to respond continually to the separation of coarse solids (ranging from sand, rocks, wood, foliage, sanitary products, toilet paper, grease, mixed food products and commercial waste), to prevent blockages and obstructions in downstream biological and/or physical processes, while minimising the overall operating strain on the plant and staff.”

CST Wastewater Solutions’ in-channel technology has lower fluid head loss at peak flows to increase solids removal efficiency compared with typical traditional screening at wastewater treatment plants, says Mr Bambridge.

“Advantages of this technology when dealing with fine screening of larger flows (5mm or finer screening on flows up to 2000 l/sec flow) include mechanical simplicity, self-cleaning and high efficiency screening for reduced maintenance and cheaper whole-of-life costs compared with other types of screens, such as band and inclined drum screen designs, for example,” said Mr Bambridge.

Functionality

CST Managing Director Michael Bambridge has experience in global wastewater technologies

Key to this functionality is the configuration of the design, in which the screening drum is installed horizontally semi-submerged in line with the incoming wastewater. The plate at the back of the drum re-directs flow radially through the mesh to optimise solids separation and self-cleaning.

The rotary drum is manufactured from either self-cleaning wedgewire for primary screening, or perforated plate for fine pre-membrane bioreactor (pre-MBR) screening. It is washed by a system of spray nozzles at a moderate pressure.

CST’s screening technology – available in 2mm and 3mm hole or 3mm wedgewire – provides for optimal adjustment of screen gap widths and sieve hole diameters for the most appropriate screening result when matched to individual installations characteristics such as the application flow and local site conditions.

An internal hopper collects the screenings, which are flumed out to the integral lifting and dewatering screw, to efficiently dewater and reduce screenings volume.

The lifting screw is shaftless to avoid any blockages, even in the presence of fibrous products, and includes screen and screening washing. Lifting and screenings handling can also be conducted outside the channel, which increases options for additional washing and dewatering, according to individual applications, says Mr Bambridge.

“Screening and the solids lifting and dewatering are separate operations, using high efficiency screening technology to convert the high-flow, low-solids wastewater to low-flow, high-solids dewatering. Separate screening and lifting equipment makes access simpler for more cost-effective housekeeping and maintenance for lower whole-of-life costs,” he says.

Advantages of Horizontal Drum Design

- Lowers operating depth and range to reduce average screen velocities for higher removal efficiencies, and easier cleaning than alternative screens.

- Increases available open area for equivalent operating depth, which enhances functionality.

- Robust construction tailored to local conditions. The one-piece, closed drum is fully assembled in a frame for installation into a channel. It incorporates a simple, long-life, robust inlet seal that can be replaced without removing all equipment from the channel.

- All parts subject to routine maintenance are located above the sewage flow, again simplifying maintenance and reducing OH&S issues.

- Screening and lifting screw equipment are proven, simple and robust technologies. No bearings or other high maintenance moving parts are located in the wastewater. Housekeeping and servicing are conducted from above the flow channel. No mechanical devices are used inside the screen drum.

- Open entry for clean collection of solids – no rag wrapping, reducing maintenance and OH&S issues. The screen zone of the lifting screw incorporates a washing system to reduce the contents of faecal matter in the screenings.

- Horizontal design also avoids issues that may arise with inclined drums, including:

- Higher maintenance costs and downtime with seal and brush replacements cycle times

- Screenings not removed positively, Inclined drums tend to have high recycle back to inlet, which is not ideal for MBR protection

- Combined screenings handling making for inflexible operation Front bearing that collects screening and rags – these foul with the seal and cause early failure

- Operators cannot see inside the drum to check on the integral lifting screw operation and general housekeeping

- Horizontal drum design also obviates any issues with band screens and bar screens with linked belt types subject to higher maintenance, or chain/link – driven and submerged parts of the drive.

Detail makes a difference

In addition to inherent advantages of horizontal drum concept, the CST design incorporates detail and operational features chosen on the basis of practical experience over many decades of work on municipal and industrial WWTPs.

Such features – focused on focused on ease of installation, longevity and serviceability – include:

- Low-profile screens that are supplied fully assembled ready for simple and clean installation. Their flexible design and screen aperture options permit the system to be matched individually and flexibly to multiple applications

- The design features independent screen and screening handling, which makes systems adaptable for a wide variety of conditions. The screen converts high flow / low solids to low flow / high solids, promoting efficiency and longevity

- Screenings are flumed as low flow / high solids out of the drum and can be drained in an integral lifting screw or flumed to outside handling system, offering further flexibility and simplicity

- Solid drum design with closed-off end and only one inlet for reliability and simplicity of maintenance. The robust main bearing located downstream out of the main high solids flow and below design flow level. The water-flushed non-metallic bearing, designed to suit in-channel conditions, has an expected life of 7-10 years.

- Robust static inlet lip seal with stainless steel insert, which runs inside a machined recess engineered for long life and effective sealing with a life expectancy of 5-10 years

- Front support wheels are located above water level and remotely greased from the top of channel

- Screenings lifting screw is shaftless screw and proven screening technology – brushes require replacement every 2-4 years

- Easy access for servicing and housekeeping. Operation and maintenance are simplified by having one moving part for low maintenance and operational costs.

“The benefits of an efficient engineering concept and thorough detail engineering have combined to produce very low whole-of-life costs when compared with most other screens, with servicing required only every 4-6 years,” says Mike Bambridge.

“These are very important considerations when dealing with local municipal authorities with budget constraints, as well as those with limited engineering resources, to whom ongoing reliability and minimal operation costs and risks are important,” said Mr Bambridge, whose international and regional experience includes both municipal and industrial WWTP engineering and green energy initiatives in partnership with local suppliers.