CST Wastewater Solutions’ major waste-to-energy project with NH Foods in Queensland has received international recognition this month through finalist nominations in both the energy and sustainability categories of the prestigious 2019 Institute of Chemical Engineers (IChemE) Global Awards.

The technology involved in the double IChemE finalist nomination is a far-sighted green energy initiative by leading meat processor NH Foods Australia at their Oakey Beef Exports facility, and is already paying handsome dividends in terms of cleaner wastewater effluent, as well as a reduced fossil fuel environmental footprint and lower energy costs.

The Global Water & Energy (GWE) COHRAL™ (Covered High-Rate Anerobic Lagoon) plant extracts green energy (biogas) from Oakey Beef Export’s wastewater streams to replace millions of dollars’ worth of natural gas over its operating life, in Queensland’s Darling Downs region.

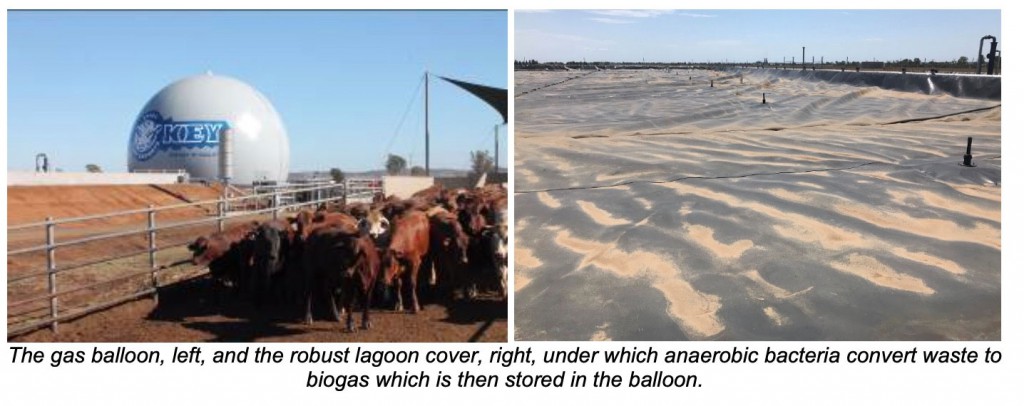

The plant – which occupies half the space of comparable technologies and stores biogas extracted from wastewater in a robust 6000m3 polyester balloon – was installed at Oakey by Australian environmental engineering and green energy authority CST Wastewater Solutions, which recently inspected the plant as it reaches its landmark fifth year of service in southern Queensland.

In addition to food and beverage processors, the technology can be applied to agribusiness operations including all forms of meat, livestock, poultry, fish and agribusiness, including fruit, sugar, vegetable, grains and other crops.

“It’s outstanding to receive this kind of international recognition, and we credit NH Foods Australia for their forward-thinking and innovative attitude to sustainability. They are leading the way in environmental and sustainable outcomes in the meat industry in Australia,” said Mr Michael Bambridge, Managing Director, CST Wastewater Solutions.

“By transforming a wastewater effluent treatment and disposal problem into an ongoing productive asset, the plant has achieved a rare business and environmental ideal of cleaner, greener performance with stable, predictable and profitable supplies of biogas,” said Mr Bambridge.

The Institute of Chemical Engineers (IChemE) is the global professional membership organisation founded in 1922 as a professional institution for chemical and process engineers. IChemE has grown to its current status of more than 40,000 members across more than 100 countries, with offices in Australia, Malaysia, South Africa, New Zealand, Singapore and the UK.

The Energy Award recognises the best project or process to demonstrate innovation in renewable, alternative or nuclear energy, efficient energy use or the development of energy production methods that reduce energy intensity.

The Sustainability Award recognises the project, process or product that best demonstrates innovation in waste reduction, recycling, reuse or the lengthening of product lifecycles.

The winners of the 2019 IChemE Global Awards will be announced November 7th at a formal awards night in Hull, UK.

Replacement of fossil fuel

The clean, compact and robust plant is in outstanding condition, having required only routine maintenance over the past five years as it continuously produces 3000-4000 m3 of biogas a day, depending on plant throughput. The generated biogas is directly used in the plant’s existing boiler replacing natural gas. This leads to replacement of fossil fuels and sharpened cost-efficiencies at a time they are most needed during the current Australia-wide drought.

Instead of effluent being stored in energy-costly and extensive aerated lagoons used by many food and beverage business – with associated environmental, OH&S hazard, water and odour issues – waste at Oakey is converted to biogas by a clean, green and reliable anaerobic digestion process applicable to any food, beverage or primary processing plant with an organic waste stream.

The compact GWE COHRAL™ plant involved occupies just half the footprint of comparable covered anaerobic lagoons and a much smaller space required by typical energy-hungry and odorous open aeration lagoons in service globally, says Mr Bambridge.

The necessary pretreatment prior to the GWE COHRAL™ system lead also to better recoveries of valuable protein and fats which would normally end up in the wastewater.

This could be classified as an indirect benefit to the bottom line as well as increasing reliability by isolating clogging waste from the high performance WWTP (Waste Water Treatment Plant), says Mr Bambridge.

“The wind doesn’t need to blow, and the sun doesn’t need to shine to produce this green energy – it is a highly viable renewable in its own right, which complements the many excellent solar and wind energy sources suited to other projects. Ultimately, the plant will pay for itself with biogas then go on to produce virtually free energy for many years after that,” said Mr Bambridge.