The latest Smith & Loveless PISTA® wastewater grit removal chamber, which extracts an unprecedented 95 per cent of grit as small as 100 microns, has been launched by regional supplier CST Wastewater Solutions.

Equipped with a new patented V-Force Baffle™ that increases the effectiveness of the grit removal, the PISTA ™chamber is “pretty hot”, according to Michael Bambridge, Managing Director of CST Wastewater Solutions.

“The standard for grit removal until now has been 95 per cent removal at 250 microns, so the same removal efficiency at 100 microns moves the benchmark well forward,” he said.

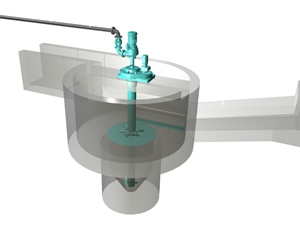

Designed for municipal and government wastewater treatment systems, the PISTA 360™ uses an integral flow chamber baffle for both the inlet and outlet of the main chamber. The baffle is designed to direct the inlet flow into the chamber in a manner that ensures the proper vortex flow and prevents short-circuiting.

The V-Force Baffle™ allows for a full 360 degrees rotation through the inlet and outlet, providing maximum travel of the wastewater for the most effective grit removal before proceeding to downstream treatment processes.

The baffle acts as a “slice weir” to control the water level in the main chamber and in the inlet channel. No additional downstream flow control device is needed to keep the velocity between 3.5 fps at peak flow and 1.6 fps at minimum flow with a 10:1 turn down.

“This innovation further enhances the world’s best grit removal system from PISTA®, which incorporates many engineering and cost saving considerations,” Mr Bambridge said.

“By increasing chamber velocity during low flow periods, the baffle extends the grit extraction path within the vortex grit chamber. This is the key, because a longer path increases the amount of grit being captured on the chamber’s flat floor.”

Grit consists of a variety of particles including sand, gravel and other heavy inorganic materials. Most grit found in domestic wastewater is made up of coarser particles of 50 mesh size and bigger.

The remainder of grit consists of smaller particles, mostly in the range of 50-100 mesh. In some coastal regions, there may be higher concentrations of finer grit, which can be smaller than 100 mesh.

The PISTA 360™ with V-Force Baffle™ permits design flexibility so that water elevations can be controlled. “Water level control is important because it upholds the proper velocities approaching the grit chamber,” he said.

“Previously, the common way to accomplish water level control was to back up the flow with a downstream submerged weir. The PISTA 360™ with its preset inlet and outlet openings supplants the need for the submerged weir.

“By integrating the water elevation settings with the baffle, the outlet footprint requirements decrease by as much as half the typical size. The resulting smaller footprint provides significant construction cost savings.”

In summary, the benefits of the V-Force Baffle™ include:

- 95 per cent grit removal efficiency down to 140 mesh particle size.

- Construction cost savings due to decreased overall grit system footprint.

- Increased grit chamber velocity during low-flow periods.

- Full 360 degrees rotation in the chamber, lengthening the grit extraction path.

- Elimination of the need for downstream level control devices.

- An ability to handle a wide range of flows.

The PISTA 360 degrees with V-Force Baffle™ is just one of many Smith & Loveless design innovations that have made PISTA® the world’s leading grit removal system for municipal wastewater systems and industrial facilities.

Published data from Smith & Loveless standardised test procedures at numerous wastewater treatment plants consistently demonstrates that the PISTA® system maintains the highest removal efficiencies in the market.

The PISTA® system, backed by extensive Smith & Loveless R&D, has progressed in design, sizing and patented components since it was first introduced three decades ago.