Sludge dewatering seldom makes the headlines environmentally in Australia, New Zealand, or Oceania more broadly, but it is an increasingly vital process in ensuring compliance with statutory groundwater, transport, disposal, and OHS regulations affecting both municipalities and industry.

Wastewater before treatment, during which sludge is deposited

Concisely defined, it is the practice of minimising waste by volume to prepare the biosolids involved for effective disposal or re-use – and in so doing, avoiding sloppy hazardous spillages during expensive transport to equally expensive and increasingly rare disposal facilities.

It is a big undertaking. The Australia and New Zealand Biosolids Partnership* estimated this year that annual dry biosolids production has risen to 372,000 tonnes. With a weighted average solids content of dewatered biosolids around 23 per cent, this equates to 1.6 million tonnes of dewatered biosolids being carried around Australia, for example. More than half the biosolids are transported between 50-400km for beneficial uses, including the improvement of agricultural land and reclamations sites, including mine sites. (*The Australian & New Zealand Biosolids Partnership (ANZBP) is a member-based collaboration of utilities, consultants, academics and government bodies committed to the sustainable management of biosolids)

Australian and New Zealand wastewater authority Michael Bambridge says sludge is produced during virtually every wastewater treatment process that must be undertaken before the water can be released back into the environment.

This ubiquitous sludge is a by-product extracted from the slurry during the many processes of municipal and industrial wastewater treatment of effluents, which can range ranging from human waste through to biological waste from industries such as food and beverage, meat, fish and agribusiness.

Sewage sludge is regarded as having become biosolids once it has undergone further treatment to reduce disease causing pathogens and volatile organic matter significantly. It is produced also by wastewater treatment plants in often remote and environmentally sensitive mining, energy, and construction plants, where recycling and the quality of water returned to the environment after the extraction of biosolids is a priority.

Curtailing costs with sludge dewatering

“Done well, dewatering can be an effective tool to reduce environmental hazards and to curb the expensive costs of transport of transport and disposal, as well as the carbon costs of transporting tens of thousands of tons of sludge over considerable distances. Disposal costs can be a double whammy, with substantial specialised transport and carbon costs – before they even get to the front gate of the increasingly rare and scattered authorised disposal sites, which must be engineered to stop pollutants leaking into groundwaters, riverine and marine environments.

“Done poorly, treatment and disposal of wet and sloppy waste can lead to hazards, both for the workers involved in removing and loading it, as well as instability of ground and soil into which it may leak. There is also strong potential for groundwater contamination if the water removed is not properly treated,” says Bambridge, who is the Managing Director of CST Wastewater Solutions.

Bambridge has more than 30 years’ experience in wastewater treatment in both countries, installing hundreds of water and wastewater treatment plants, filtration plants, anti-grit technologies from world leader Smith and Loveless, as well as waste-to-energy plants for major food and beverage organisations. His company extends its commitment to environmental quality by fully manufacturing its rotary drum screen and screw screen/compactors in Australia, thus enhancing quality assurance, environmental outcomes, and availability of backup service to ensure optimum performance continues even during times of stretched supply lines – and in the event of environmental emergencies, with their statutory obligations and reputational risk).

Mountains of water-borne garbage screened out before wastewater treatment, left, and drier, less sticky and more compact treated sludge from downstream water treatment processes, right

SMEs benefit from low maintenance solutions

As well as large WWTPs for some of Australasia’s largest public and private water and industry clients – many now using the ruggedly dependable and low maintenance locally manufactured product – CST Wastewater Solutions also sees a strong need for better sludge treatment for small-to-medium public and private organisations. These range from primary production sites (including food and agribusiness) through to remote communities without sewered services but with strong environmental requirements (including Lord Howe Island, for example). They also include the resources and construction projects that dot the maps of Australia, New Zealand and Papua New Guinea, where there is an expanding consciousness that water is a vital shared community resource that must be protected.

“Water and wastewater treatment and water recycling is not a one-size-fits-all,” says Bambridge.

“You have to engineer quality inputs to get quality outputs, not buy the cheapest and most unsuitable import that appeals only to short-term bargain hunters, who have no experience of what might happen if and when it breaks down or needs service from the other side of the world. Many such short-sighted people will not even be there if, and when, something goes wrong with their cheap deals a few years after they have moved to another job. Water treatment isn’t for bargain hunters.”

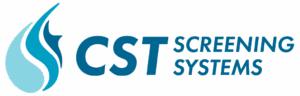

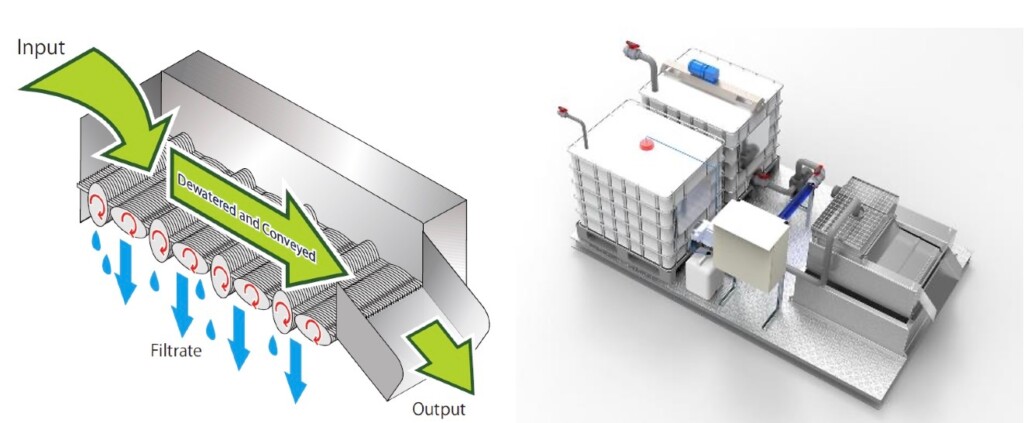

One advanced technology in the treatment of sludge is KDS’ separator with unique self-cleaning action, left, which is available in hydraulic capacities from 264-4092 gal/hr (approx. 1000-15490 litres) with input solids content of 2 per cent. It also comes in skid-mounted plug-and-play configurations, right

To cater for the small-to-medium end of the market, Bambridge’s company is employing advanced technologies in the region, such as the Japanese-made stainless steel KDS low-maintenance liquid-to-solid waste separator, which reflects the cleanliness and quality ethos of its country of origin.

“The KDS separator is right for environmentally aware small-to-medium operations, because it uses a fraction of the power of a centrifuge and consumes no water during operation, unlike a belt press or a screw press. For a relatively low investment cost, it offers a high-performance alternative to sludge drying beds and geobags, for example,” says Bambridge.

KDS separator benefits

Used for thickening of dissolved air flotation sludge – a very common application throughout wastewater operations – the KDS achieves solids capture of 97 per cent thickened sludge at a dryness of 17 per cent. Waste activated sludge dryness levels are typically 15-25 per cent.

Where sodden waste and transport costs are an issue, KDS technology offers a solution

KDS technology removes more than 50 per cent of the water from wastewater sludge to provide a 50 per cent reduction in transportation costs. It features a unique self-cleaning dewatering and conveying system with oval plate separation and transfer structure that prevents clogging and permits automatic continuous operation that handles oily and fibrous material with ease

Small-to-medium applications for which the separator is designed include:

- Sewage treatment, including raw wastewater (primary screening) and sludge to landfill

- Remote communities using septic or systems producing low-quality output.

- Resources and construction sites wanting to optimise the output quality and recycling potential of the water resources they often share with nearby communities

- Intensive livestock and aquaculture operations, including abattoir, feedlots, fisheries, poultry and dairy farm wastewater and sludge. Cattle manure cake dryness of 25-35 per cent is typically achieved

- Food and beverage processing waste, including snack foods, kitchen and restaurant waste, brewery waste, raw wastewater (primary screening) and sludge.

- Pig farm raw manure and sludge, with cake dryness of 20-30 per cent.

- Barrel polishing water, water-based paint wastewater, grease trap waste, dyeing wastewater, waste oil, and plastic recycling.

“The new skid-mounted KDS technology offers potential users a highly effective plug-and-play solution to waste processing needs,” says Bambridge. Measuring only 3.8 by 2m, it offers the type of low-maintenance high efficiency that is so important where agribusiness, industrial and municipal operations don’t have the resources to place engineering staff on close standby.”.

CST manufactures locally for quality control of these fine-mesh rotary drum screen and screw screen/compactors

CST Managing Director Michael Bambridge has more than 30 years’ experience in global wastewater technologies

While the KDS system is in service extensively internationally as well as Australia and New Zealand, Bambridge says he emphasises it is one of a variety of valuable tools available to organisations seeking quality responses to their particular needs.

For example, at the large end of the scale, he has installed a large scale GW&E COHRAL™ waste-to-energy anaerobic digestion system for the Oakey export meat works of NH Foods. CST Wastewater Solutions has also installed multiple Smith and Loveless FAST® (Fixed Activated Sludge Treatment) process self-contained water treatment systems delivered as a container to Australian mine sites.

“As environmentally aware and quality-focussed wastewater treatment professionals, we don’t ever propose that just one solution is the answer to all water quality issues – that would be absurd. There are many excellent technologies out there, of which KDS is an example in the small-to-medium separator category.

“Our main message to environmentally responsible organisations is to engineer for future quality of water output and reliability. Don’t just join the race to the bottom, on upfront pricing alone. Typically, what that does is transfer problems down the line, where the costs can be far greater. There is always a reason why things are cheap. Our water resources deserve better.”