Advances in wastewater technology are opening up new opportunities for local government and food producers to cost-efficiently solve water quality, water recycling and green energy challenges previously consigned to the too-hard basket. Here MIKE BAMBRIDGE* shares his extensive experience of Australasian and global municipal waste water schemes to show where such technologies can produce both OH&S benefits for council staff, while delivering ratepayers and industry benefits including cash-from-trash green energy plants. The technologies will be on show at Food Technology Queensland from June 26-28

The job of local authority waste water managers is becoming increasingly demanding as agricultural, industrial and urban ratepayers compete for the same water resources, which are themselves often declining in quality and shrinking in quantity.

And as urban spread and industrial and agricultural uses intensify and overlap – and global warming causes even greater biological load concentrations and evaporation – waste water managers need to respond with proposals that meet ever increasing statutory health and safety requirements.

The end result is that today’s waste water managers have to design and operate their plants to a much tighter and more demanding sustainability brief. Stricter requirements extend from increasingly careful handling of waste inputs (OH&S requirements), through to strict control of outputs, particularly in terms of water quality, effluent and leakage into water tables affecting agriculture and fisheries.

The good news is that effective technologies are available to address these issues, if you know where to look for solutions such as advanced fine screening, UV disinfection, membrane and aerobic and anaerobic digestion, filtration and reverse osmosis for example.

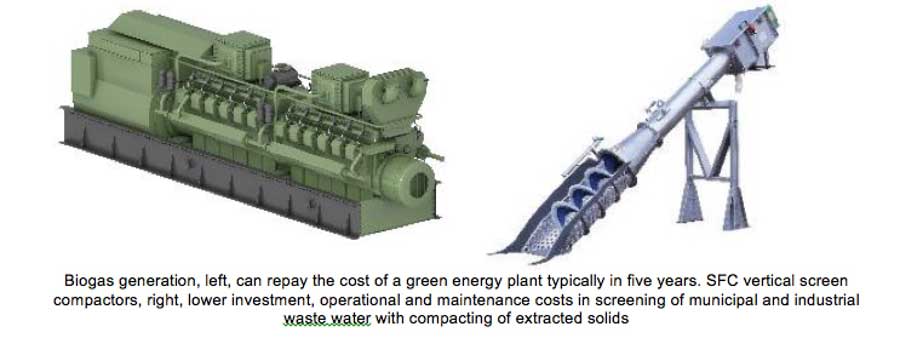

The latest fine screening technologies – the start of any effective system – are not only simpler and less expensive to operate, with fewer OH&S hazards for staff to pick through, but they also reduce downstream operator intervention. Good pre-treatment allows the optimum conditioning of wastes to enable a more efficient conversion into biogas (methane) and recyclable water.

Biogas generation, left, can repay the cost of a green energy plant typically in five years. SFC vertical screen compactors, right, lower investment, operational and maintenance costs in screening of municipal and industrial waste water with compacting of extracted solids

Such locally manufactured and installed technologies are already reducing maintenance, landfill and OH&S issues for Australian and New Zealand organisations.

Globally proven aerobic water quality and green energy technologies are also proving to be profitable, easily maintained and cost effective (with Global Water Engineering technologies, for example, proven in more than 400 projects worldwide).

One such cash-from-trash project recently won a global award from the Institution of Chemical Engineers, IChemE, which represents more than 40,000 engineers globally. It not only transformed the agricultural pulp involved into biogas, but in so doing also eliminated a smelly disposal and landfill problem.

Another municipal waste-to-energy project – using technology available in Australasia – is designed to convert more than 65,000 tons of mixed organic waste a year into environmentally harmonious green energy and dry fertilizer. It will process more than 15 different waste streams into biogas to generate electricity as well as dry bio fertilizers. The plant – incorporating a Global Water Engineering (GWE) RAPTOR™ (which stands for Rapid Transformation of Organic Residues) system – harvests waste such as grocery store rejects, kitchen and market waste, food processing residues, leachate, manure, and slaughterhouse residues, which it converts into enough biogas (primarily methane) to generate 2.85 MW of electricity and 8.7 tons a day of dry bio fertilizer.

LEFT: Members of Australia’s Meat Industry Processor Corporation (AMPC) Environment Network saw the theory of turning trash into cash transformed into action recently when they visited Oakey Beef Exports in Queensland. The technology used in this purely private enterprise initiative is also widely applicable to public-private partnerships. RIGHT: Another private enterprise success story, Bluetongue Brewery on NSW’s Central Coast made more beer with less water using a state-of-the-art CST water recovery plant.

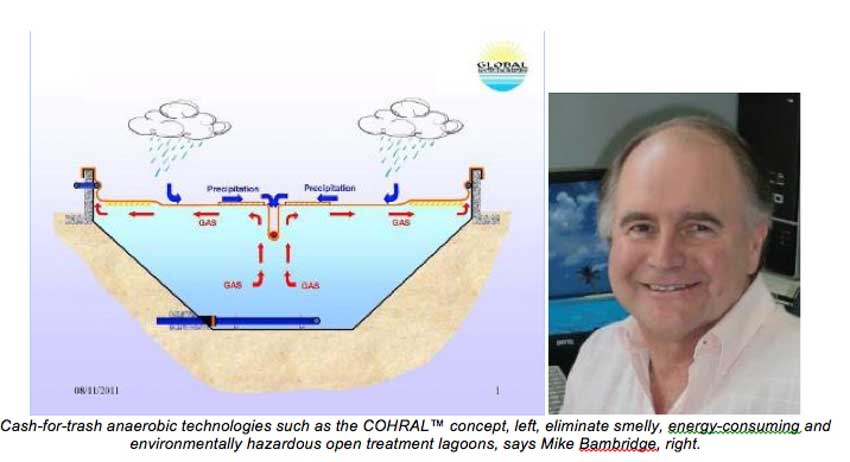

Exactly the same RAPTOR™ anaerobic technology is already available in Australasia, along with the latest Covered High-Rate Anaerobic Lagoon (COHRALTM) technology, which a major Australasian meat production plant is introducing to cleaning up waste water to high effluent standards while storing the methane produced in high safety balloon structures for use on demand.

So green energy installations such as these are readily adapted to joint local authority/private industry ventures – where local government takes the lead by bringing together some of its major producers of waste and effluent to collectively solve a common problem.

But – as a recent New Zealand and Australian green energy survey showed – the best combinations just can’t be picked off the shelf to fit particular projects. They have to be engineered for local conditions or they won’t deliver on their promise. (See the full survey here.)

Cash-for-trash anaerobic technologies such as the COHRAL™ concept, left, eliminate smelly, energy-consuming and environmentally hazardous open treatment lagoons, says Mike Bambridge, right.

And that’s the key: Technologies that work in applications for which they are designed. Performance promises that are kept. Engineering that will bear peer review. And experience that can show where waste-to-profit promises have actually worked in practice rather than theory, as with the successful and functioning examples to which this article refers.

Conclusion: re-thinking projects to fit in with ever-changing regulations and environmental requirements

Individual companies are naturally self-interested in many cases, so it requires an outside agency – the Government in this case – to bring them together with local government in forums to discuss the issue collectively. Ultimately there will probably need to be incentives to consider investment in waste-to-energy and to stop wasting waste. Waste is a profitable resource which, properly treated, produces both profit and good environmental incomes, in the form of biogas and clean water for recycling.

There is a strong commonality of interest involved. We have big emerging community water issues in Australia, with farmers and horticulture being forced off the land because there is just not enough water for them. This is particularly relevant when I see farmers using their land for coal seam gas and wind towers and solar – why not make money from waste as well?

Then we know also that drinking water resources of some municipalities are themselves under threat. This is pretty drastic, and the time is well and truly here when we should have private industry, local government and State and Federal Governments working in partnership on an issue that affects them all. The first step is to get some consensus, as Bob Hawke used to say. Properly informed people have a better chance of making better decisions for the collective good.

Whether this happens at a local area level – which is probably a good idea – or whether it happens on an industry basis is not as important as the need for the process to get started.