A leading New Zealand food processing company committed to ongoing excellence in sustainability has become an early adopter of a sludge dewatering technology engineered to cost-efficiently reduce the environmental footprint of food, beverage, and wastewater treatment throughout Australasia.

The harvest of fresh ripe red apples just collected from the trees are folded into large wooden pallet containers. A sunny autumn day in farmer’s orchards. Production capacity of a orchards farm.

The international fruit processing facility in Hawkes Bay (which cannot be named for contractual confidentiality reasons) processes tens of thousands of tons of fruit for both local and export markets, using a compact and cost-efficient KDS multidisc roller system from CST Wastewater Solutions as part of their process.

The low-energy KDS technology from Australian company CST Wastewater Solutions dewaters wet, sloppy screened waste from the processing of fruit such as such as apples and pears, reducing waste volumes by up to 90 per cent.

It transforms the waste to a much drier product that is less messy, easier and hygienic to handle, and cleaner to transport for recycling to stockfeed for the rich agricultural region of Hawkes Bay.

In addition to saving fossil fuel and other transport and disposal expenses – which can amount to hundreds of dollars a ton – the drier waste helps protects water tables and conforms with the strong environmental and pure food credentials of the processor.

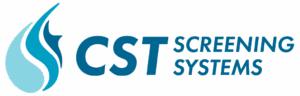

KDS technology with its multi-roller system (above) eliminates sticky processing spillages by producing a drier, waste that is more easily transported and recycled) (See animation of the rollers here. See a video of the KDS used in fruit processing here.)

KDS technology with its multi-roller system (above) eliminates sticky processing spillages by producing a drier, waste that is more easily transported and recycled) (See animation of the rollers here. See a video of the KDS used in fruit processing here.)

The fruit processor – located in an area famous for its fruit production – has previously won an export award in which the judges of which said they liked the level of engagement across the wider team in developing the company vision, and the continuous improvement and commitment to innovation was genuinely impressive. The factory was well laid out and the effort that was put into health and safety stood out.

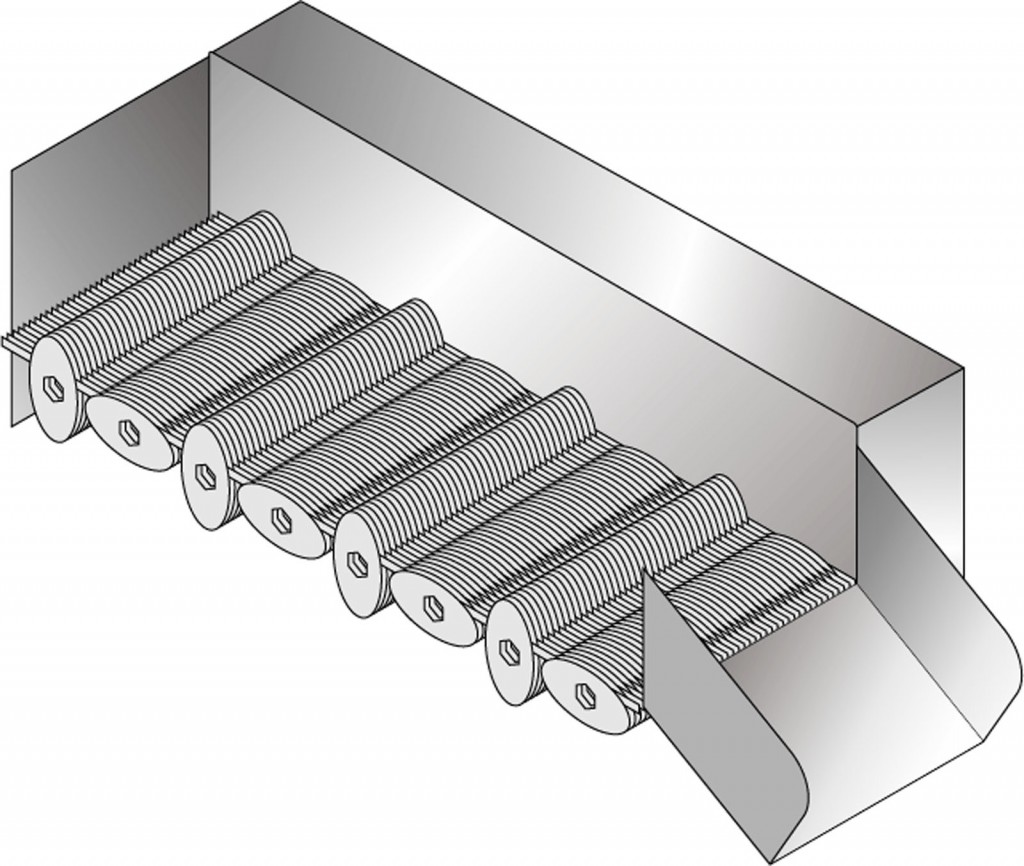

The KDS (shown left) creates a much drier output from fruit waste, shown bottom left, and right. This drier output reduces waste volumes by up to 90%

CST Wastewater Solutions Managing Director Mike Bambridge said the durable stainless steel KDS technology was another step forward in the company’s cleaner/greener process enhancements and new state-of-the art facilities, which are designed to benefit the entire region and community of which the company is part.

“In service, the KDS technology does everything it is meant to. It is true to its claims,” said Mr Bambridge, adding that the KDS typically handles 6m3 (approx. 100-150kg) per hour of sloppy waste containing leaves, twigs and unsuitable fruit. The output is transformed into waste for disposal or stock food, that is much cleaner, neater and healthier to handle.

“Reducing waste volume by up to 90% radically reduces transport costs and helps prevent any potential spillages onto public roads during transport. Both issues are very important, with rising specialised waste disposal transport costs and with local communities and councils very mindful of how companies treat waste. The company using the KDS technology is setting an example of good practice in both areas.

Wet, sloppy fruit waste is eliminated by KDS technology, which produces a lighter, drier, and more hygienic waste product (left). KDS technology is also available as relocatable skid-mounted types (right) which can be easily transported by truck or trailer to remote, sensitive or difficult access sites.

Wet, sloppy waste is eliminated by KDS technology, which produces a lighter, drier, and more hygienic waste product (left). KDS technology is also available as relocatable skid-mounted types (right) which can be easily transported by truck or trailer to remote, sensitive or difficult access sites.

“It is a win-win environmentally and operationally because there are both operational and OH&S benefits, with the site being cleaner and easier to maintain and the financial gain of not paying for transport and disposal of unnecessary water. Heavy cakes of byproduct from growers and food processors generally can cost upwards of $150 a ton to dispose of, including the specialised transport from the places where trade wastes are generated, to centres where compacting, drying, recycling and disposal can take place in controlled environments,” says Mr Bambridge, who worked with CST Wastewater Solutions NZ Manager Mr Pieter Groenewegen during the installation.

The fruit processor uses the KDS technology to handle a highly variable quality and volume of up to 6m3/h. “This first NZ adopter of the KDS technology had previously tried alternative technologies, but none handled the variable volume involved or dewatered the fruit waste enough to prevent excess water and product from creating an unhygienic site and causing leakage,” said Mr Bambridge.

The application uses a KDS model SS611 with a longer press zone, to achieve optimum dewatering of the sloppy and wet mix of peelings, leaves and pulpy fruit material.

“The dewatering concept being employed in this instance is to spread the waste over the table width and dewater a mat of material, to maximise the surface area and minimise water retention.”

“This is an outstanding application of this globally proven technology, which is eminently suited to the food and beverage processing industry. It also very cost-efficiently advances the environmental credentials of a significant member of the Australasian fruit industry, while being a major contributor to the local and export agricultural market,” said Mr Bambridge.

Other KDS applications include thickening and dewatering of Dissolved Air Flotation (DAF) sludge – a very common wastewater application – the KDS achieves solids capture of 95-99% sludge at a dryness of 15-20%. Waste activated sludges are typically 15-18% dryness. This high quality, Japanese-manufactured technology:

- Uses minimal energy, consuming as little as 0.06kW hr of electricity

- Operates at low (63dBa) non-intrusive noise and vibration levels

- Does not need water to keep clean, eliminating aerosol OH&S problems

- Requires minimal daily maintenance, saving cost and enhancing OH&S performance

- Occupies typically half the space or less of conventional dewatering plants

- Is engineered to overcome the limitations of technologies such as screw presses, belt presses and centrifuges typically employed by small-to-medium applications to treat the sludge produced by their operations.

The mid-size KDS unit can handle about 100kg DS (dry solids) an hour at 98 per cent solids capture, says Mr Bambridge. The largest unit can handle 310kg DS an hour.

This lighter, dryer waste produced – in addition to being easier and cheaper to transport – reduces the labour for cleaning and cleans up transport operations for any fruit, juice, vegetable, and food production facilities, including kitchens and catering. In fact, this applies to any livestock, horticulture, agribusiness producing waste during production and processing.

The technology is also suitable for municipal and remote industrial worksite waste handling. where its cost-effectiveness and low-maintenance operation is a major advantage where engineering support may be far distant.